Transcribed by Jane from The Newry Commercial Telegraph Thursday, November 30, 1871

photograph by the Ulster Architectural Heritage Society https://www.flickr.com/photos/uahs/

The Manufactures and Trades of Newry and Vicinity. The Spinning Trade.

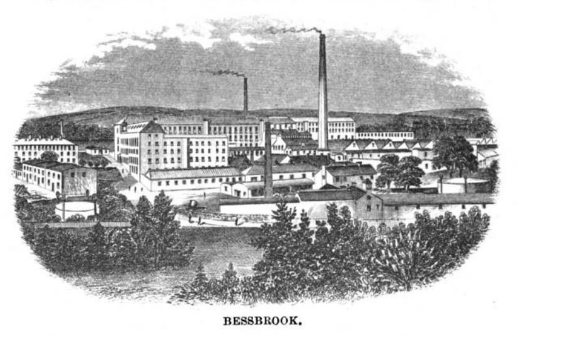

“The Bessbrook Spinning Company” No. II

In our introductory article we referred to the extensive employment of labour at the Bessbrook Spinning Mills, and it is now our intention to refer more particularly to this great centre of industry and commerce. From a very early period we find that the Bessbrook district was exceedingly famed for its large manufacture of linens; in the year 1818, for instance, there have been exported from Newry linen cloth to the value of £472,000. About the year 1810, finding the linen trade so successful, an effort was made by the ATKINSONs, of Millvale and Glenanne, to establish the manufacture of cotton goods, and, with this object in view, several cotton mills were built in the valley of Glenanne, but unfortunately the speculation proved very unsuccessful.

The principal part of the linen so manufactured at this period was bleached and finished at the several large works built along the stream from Camlough to Newry; and from Coote’s survey of the County Armagh, in 1800, we observe that he estimates the number of pieces finished at the g? of Mount Caulfield, Bessbrook, and Craigmore at 50,000 webs, or 1,250,000,000 yards. Referring to the large trade carried on in the district at that period, Coote says: – “In this line (the Camlough water line) is the small village of Camlough, so named from the celebrated lake of Camlough, which is worthy of particular notice on account of the rapid stream that flows from this small sheet of water, and performs more actual work, in a line not quite two miles, than can, perhaps, be equalled in any part of Ireland; and the numerous works on its banks furnish an eminent instance of the superior spirit and industry of the people in this province, who so eagerly seize every natural advantage for furthering and increasing their trade.” Mr. POLLOCK’s bleaching greens at Bessbrook were capable of producing 14,000 pieces per annum, and were, for a while, successful; but whether it was that trade became dull, or that the proprietor did not persevere in that spirit of progress which the increasing requirements of the trade necessitated the concern passed into the hands of Mr. Joseph NICHOLSON. [Mr. J. NICHOLSON is now living at Crenageal, near Portadown, and is J.P. for this county.] In the year 1808 Mr. NICHOLSON built at Bessbrook, if not the first, at least one of the first spinning-mills in Ireland, in which a very fair amount of business was carried on until 1830, when the place was burned by an accident, nothing but the walls remaining to testify to its previous existence. Seven years after Mr. NICHOLSON commenced to spin there were only six spinning-mills in Ulster, and during the intervening period Mr. GORDON, of Sheepbridge, made an unsuccessful attempt to spin linen yarn. The old process of spinning by hand seems gradually to have been discontinued, till it disappeared altogether.

From the year 1830 to 1844 there was no attempt made to revive the trade at Bessbrook till the property was purchased by Messrs. RICHARDSON, Sons & OWDEN of Lisburn and Belfast. These gentlemen were not slow to perceive the many natural advantages the locality possessed, and soon after commenced to build the present works. Under the management of Messrs. William and Albert DAWSON, which for a while were exclusively devoted to spinning. Being comparatively small, the mills were driven by a turbine water-wheel, and a 60-horse power steam engine, made by Messrs. Benjamin Hicks & Co., of Bolton. In the year 1850 the mills were still further raised – another storey with roofing being added. There was also an additional steam engine of 60 horse power, supplied by Messrs. M’Adam & Co. of Belfast brought in to work.

In 1854 immense weaving accommodation was added to the already extensive establishment, and also another pair of steam engine, of twenty-five horse power each, were erected by Messrs. Coates, of Belfast. In 1864 these two last-mentioned engines were replaced by two extremely powerful (40-horse powereach) horizontal engines, made by Messrs. Kay of Bury. About this time Mr. William RICHARDSON died, and the co-partnership of RICHARDSON, Sons, and OWDEN was dissolved, and an arrangement made whereby the whole concern came into the hands of Mr. John Grubb RICHARDSON, who, with Mr. William DAWSON as his partner, carried on business under the style of “The Bessbrook Spinning Company.”

The next noteworthy improvement was the introduction of the manufacture of damasks; and in 1866 another pair of engines of still greater force (50-horse power each) were supplied by Messrs. Kay, of Bury. About this time Mr. DAWSON retired from the concern, and Mr. RICHARDSON then made his son (Mr. James N. RICHARDSON) with Mr. Henry BARCROFT, and Mr. Frederick HARRIS, his partners, still, however, continuing to carry on the business under the name of “The Bessbrook Spinning Company.” There have been no further changes.

This brings us up to the present date, and we shall now give a few statistics to show the present extent of this large and flourishing concern. The roofings of the mills – including weaving sheds – cover an area of about four acres. Employment is given to 8,000 people – including men, women, and children, and an annual sum of £82,000 is paid them as wages. The articles manufactured at the present time are coarse linens, suitable for clothing in hot countries; drills, fine linens, shirtings of the best quality, famed all over the world; damasks, sheetings, and towellings. The quantity of flax required during the year is 1,800 tons, bought at a cost of £110,000; the quantity of coals consumed during 1870 was 10,000 tons, representing a sum of £6,500; and oils for a similar period cost £5,000. In the mills there are 22,000 spindles, and 700 looms; the quantity of yarn spun is 520,000 bundles, and the line manufactured averages 67, 000 pieces, or 4,000,000 yards, per annum. The company export quantities themselves to France and Germany, but the chief trade is carried on between them and the English exporting merchants; the home markets are also extensively supplied by the company. We cannot close these remarks on the Bessbrook Mills without referring to the town itself. It is only a few years since it was built in order to provide accommodation for the workers at the mills – a great many of whom previously had their dwellings in various parts of the surrounding country. The workers now have very commodious houses at reasonable rents provided them by Mr. RICHARDSON, and every encouragement to leading lives of industrious and honest labour is readily placed at their disposal. The town is about three English miles from Newry, and is very advantageously situated in a beautiful and highly fertile part of the country. The neatness, cleanliness, and regularity everywhere observable, are quite proverbial, and Bessbrook, though its population is now about 3,000, has not experienced, as yet, any pressing necessity for such institutions as public-houses, pawnshops, and police stations. The grounds about the mills are very tastefully laid out, and on inspecting them would suggest the idea of a gentleman’s demesne rather than the surroundings of a public manufactory. There are also several well-conducted schools, a reading- room and library, the Friends’ Meeting-house, the Presbyterian Church, and an Episcopal Church, all in connection with the town; and provision stores, conducted on the co-operative principle; a dispensary, in charge of an efficient medical practitioner; a good temperance hotel, and various other establishments essentially necessary to any town.

Thus has Bessbrook risen, and progressed, and from having only a very few houses has gradually extended and increased, until it has assumed its present extensive dimensions. The rule of the energetic and philanthropic proprietor is to employ only those whose character, for sobriety, steadiness, and uniform good behaviour can bear the strictest investigation, and it is to this fact principally that the success of Bessbrook may be attributed. A word before concluding, on the interior of the mills. Smoke and dust and heat do much injury in any place if the proper preventive measures be not taken. In examining the various departments at Bessbrook, however, the most scrupulous can see nothing with which to find fault, for the leading characteristics of cleanliness and order so observable in every part of the town is strictly enforced, and willingly attended to inside the mills.